Model | BS-107 |

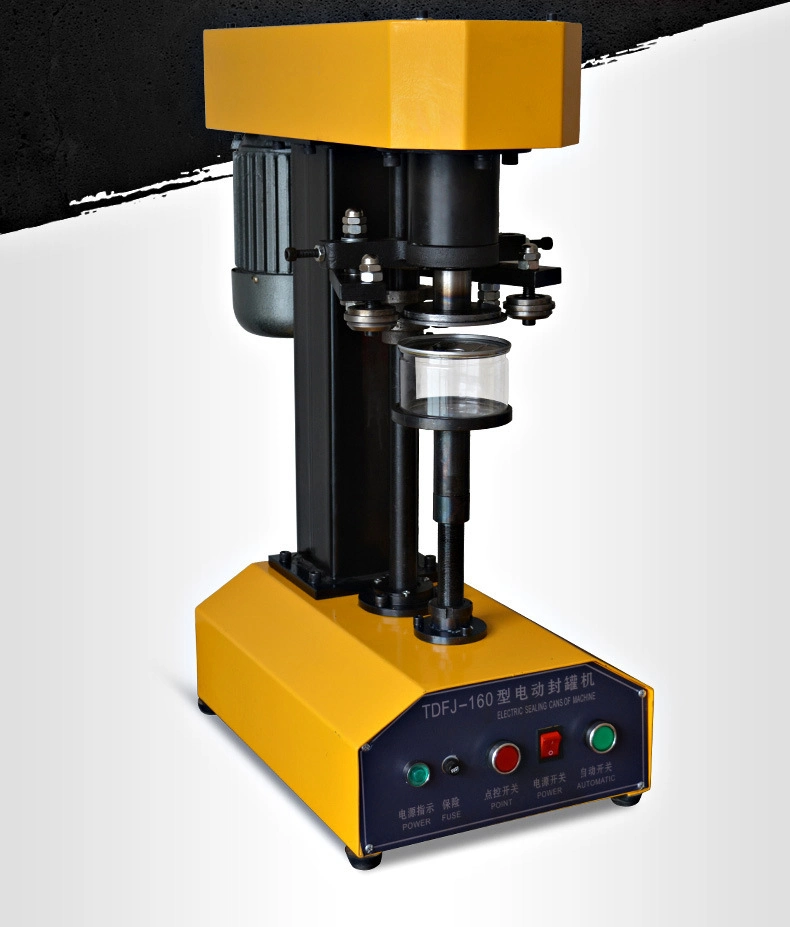

Driven type | Electric |

Voltage | AC 220V 50Hz / 110V 60Hz |

Power | 370W |

Can diameter | 45-110mm (can be customized for bigger size) |

Height of can | 39-200mm(can be customized for bigger size) |

Working speed | about 25 pcs/min |

Package size | 60*32*70cm |

Gross weight | about 70kg |

Introduction

Quality is reliabler ruffled even no fold, no leakage.Easy operation and lighter, the use of lighting power supply, one person can complete the operation.

Price higher than 150 mm to heightening of tank, plus another 360 or so

Original mold a set of machine (a set of mould seal a diameter)

Plus the mould can also be customized in our company

Higher than 150 mm to heightening of tank,Can be customized.Original mould machine a set of (a set of mould to seal a diameter) plus the mold can also be customized.

Operation Highlights:

Preparations before starting

Check whether the parts oiled.

Check all parts in case any is loose,and check the electric wires,too.

Check if the motor and movement mechanism are faulty or have any abnormal sound.

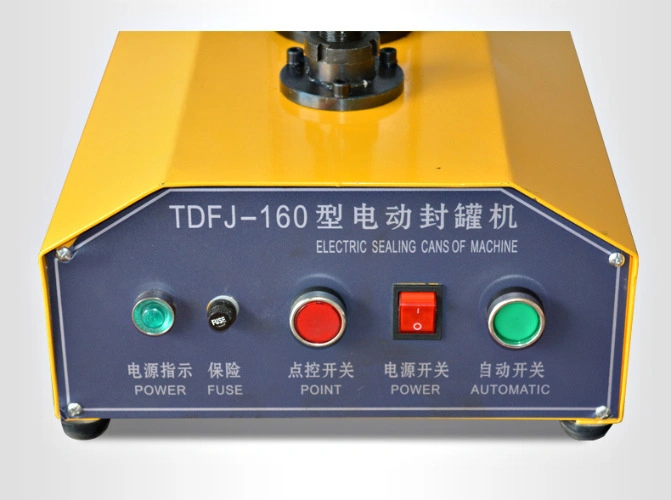

Adjustment

Press the switch to slowly adjust the Rotary screw lift to the desired height the can needs. The can sealing can be completed when it goes through both of the first roller and the seconder roller .

You need to adjust the 2 rollers to be suitable for the can sealing .

Start Sealing

Start the machine

Place the can with its cap in the correct loaction , then press the foot-pedal

Precautions

No pull or squeeze the power cord.

Only a damp cloth to wipe the machine. Do not use water to wash it.

No pressure on the machine .

When the machine is working , any adjustment is forbidden

Routine Maintenance:

Maintenance Notice

clean surface of the device,and don't place any material on the the machine .

Check and fasten the parts,and lubricate them.

Clean the roller once a day.