Features :

1.Special load cell with high precision and high standard;

2.With intelligent multiple sampling stable mode, make weighing higher accurate;

3.Intelligent fault alarm, convenient maintenance;

4.High speed staggered discharging function, effectively prevent blocking materials;

5.With high integrated modular design and CAN bus technology;

6.Modbus industry standard communication protocol, realize the interface combination of multihead weigher and packaging machine;

7.Other features are the same as first generation models.

Techanical and Character :

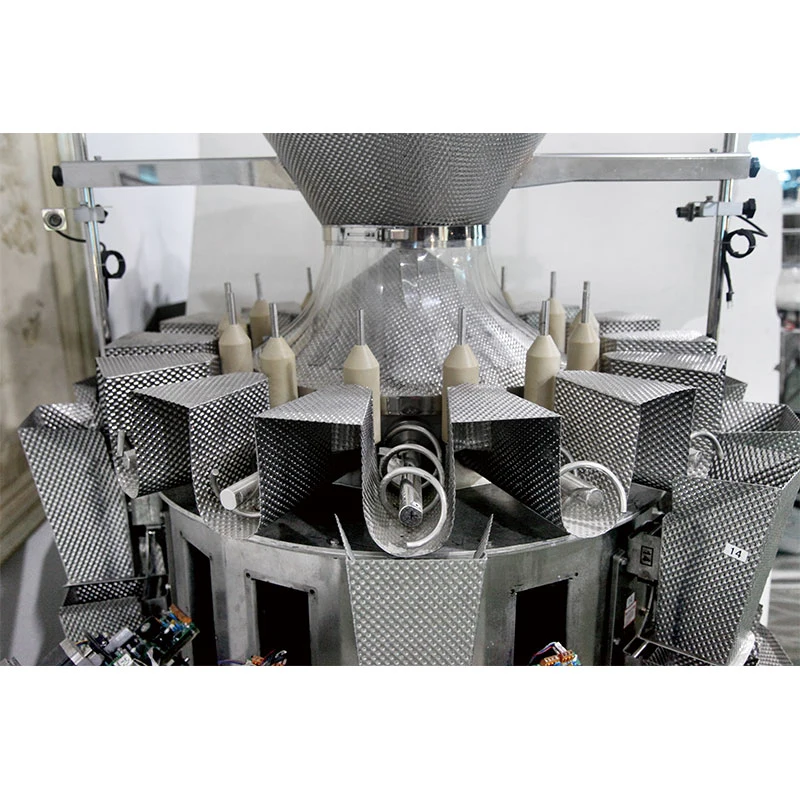

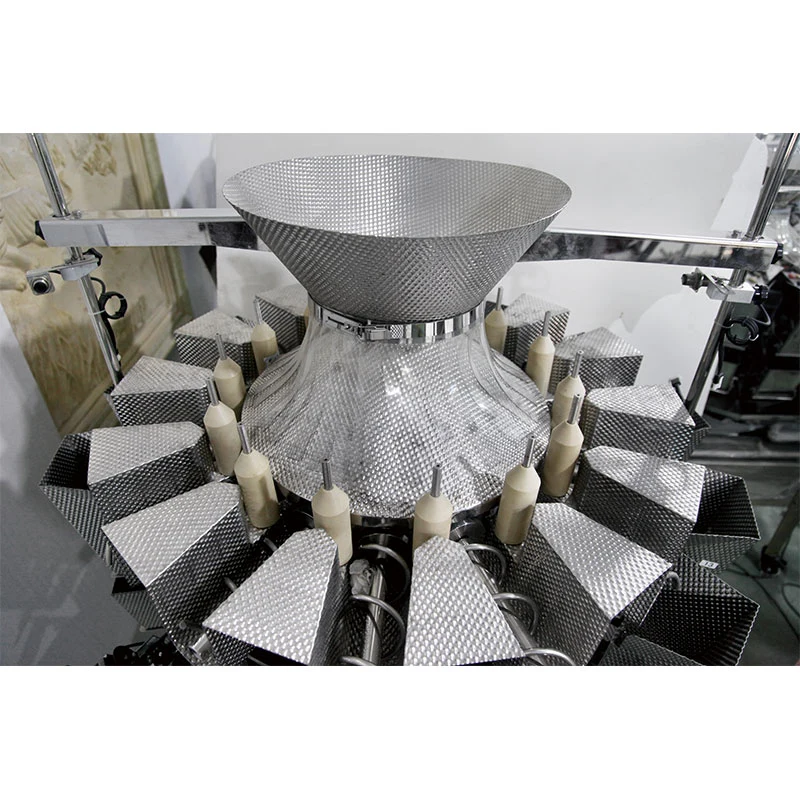

1.Screw feeding to replace the traditional vibrator feeding, it's more suitable for sticky material;

2.IP65 waterproof machine case, material contact part with dimple plate, 60° discharge chute let the material fall smoothly;

3.Drying device for optional, effectively prevent the electrical components from damage because of humidity;

4.Uniform design standards contribute to better interchangeability for spare parts.

5.Stable actuator shell structure makes the hopper running more stable and reading higher accuracy.The integral machine case and the seat enhance the strength of the machine,makes the hopper shorter stable time.

Technical Specification :

| Model | JW-A14 |

| Identify Code | A14-2-3D |

| Weighing Range | 10-1500g |

| Accuracy | x(0.5) |

| Max Speed | 50P/M |

| Hopper Volume | 2.5L |

| Control Panel | 10.1" Touch Screen |

| Options | Dimple Plate/Timing Hopper/Printer/ Reject Device |

| Driving System | Step Motor |

| Power Requirement | 220V/1500W/ 50/60Hz /10A |

| Packing Dimension(mm) | 1750(L)X1130(w)X1450(H) |

| Gross Weight | 500kg |

Application:

It's suitable for weighing the sticky material,such as chicken,pork,duck,fish,beef and so on.

Our Factory:

Certificate:

Exhibition:

Activity:

Service:

Pre-sale Inquiry

We will help you customize an appropriate weighing and packing solution based on your requirements and specific circumstances.

Installation Service

We will send professional technicians for on-site installation and commissioning upon request.

Maintenance Service

Kenwei provides long term maintenance service,any maintenance parts are free within the warranty period and only charge parts expensed if your warranty has expired.

Employee Training

Kenwei offers free technical training for our clients to fully master correct product maintenance techniques.

Custom Service

Kenwei designs custom production lines for our clients according to specific weighing and packing products,output,packing styles,factory area and other factors.

Guangdong Kenwei Intellectualized Machinery Co.,Ltd. is currently a large production base of multihead weighers. As a professional manufacturer, we devote to R&D and manufacturing of multihead weighers, linear weighers, check weighers, metal detectors with high speed and high accuracy. We also provide customers with complete automatic weighing and packaging systems to meet the various customized requirements.

Kenwei, located in Hi-tech Industrial Zone, owns modern workshop over 21000 square meterwith annual production capacity of more than 5,000 sets of multihead weigher . We have a high-quality team that professional technicians more than 30% with comprehensive capacity from design and development, manufacturing, marketing, installation and commissioning, technical training,after-sales services and providing automatic weighing packaging system customization.With the development of international markets, more and more marketing and service networks are established all over the world. We won trusts and good reputations for good and fast services, which also help us to establish good brand image in the packaging machinery industry We are now selling machines to more than 80 countries in the world.